|

|

|

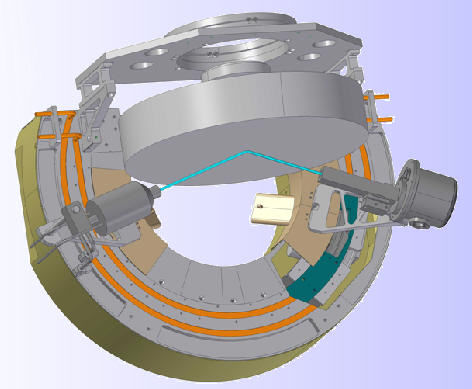

UHV Compatible DesignDesigning parts and mechanisms that have to operate in a vacuum environment requires special measures to ensure that the vacuum conditions are not comprimised and the mechanism keeps performing. Scientec has lots of experience in applying the necessary design rules, materials, components and lubricants. Below, one of the latest designs is shown. Pictures of other projects can be found in the gallery.Project example: X-ray monitor.Scientec has designed a X-ray monitor system for a Dutch research institute1 doing research on multilayer coatings. Multilayer coatings reflect soft X-ray radiation (EUV) by employing positive interference from reflections at multiple layer boundaries. A wavelength of great interest nowadays is 13.5 nm for use in future generation wafersteppers. Mirrors for this wavelength consist of alternating layers Mo and Si with a typical layer thickness of approx 3 nm.To match a set of multilayer mirrors the layer thickness has to be controlled with an accuracy of 1.5 pm. The layer thickness is controlled with the X-ray monitor. During the coating process a narrow x-ray beam is directed at the substrate surface. The reflected beam passes two slits and falls onto a detector. The measured intensity is representative for the layer thickness. The angle of the probe beam determines at which layer thickness the reflection is maximal so control of the source-substrate-detector angle is the key to accurate layer control. |

||

From left to right Dr. F.Bijkerk (FOM) and Ing. C.Bruineman (Scientec) with the new XRM. |

|

|

|

To achieve accurate angle control of the arms with respect to the substrate special measures have been taken: - source and detector are guided by a circular recirculating ball guide mounted on a closed baseplate and actuated with stepper motors through a 3 stage gearbox. - the frame is mounted in the vacuum system as close as possible to the substrate shaft fixation. - source and detector position are measured with a linear optical encoder mounted against the guide rail. The system features shielding to protect the mechanism against contamination by deposition particles. All components are UHV compatible, the coating facility operates at 10-9 mbar. This is the second monitor system which has been designed and build because of the success of the first one. Minor changes resulted in better readhead alignment and position control. 1: FOM institute for plasmaphysics Rijnhuizen in Nieuwegein | ||

|